In-house

integrated

production

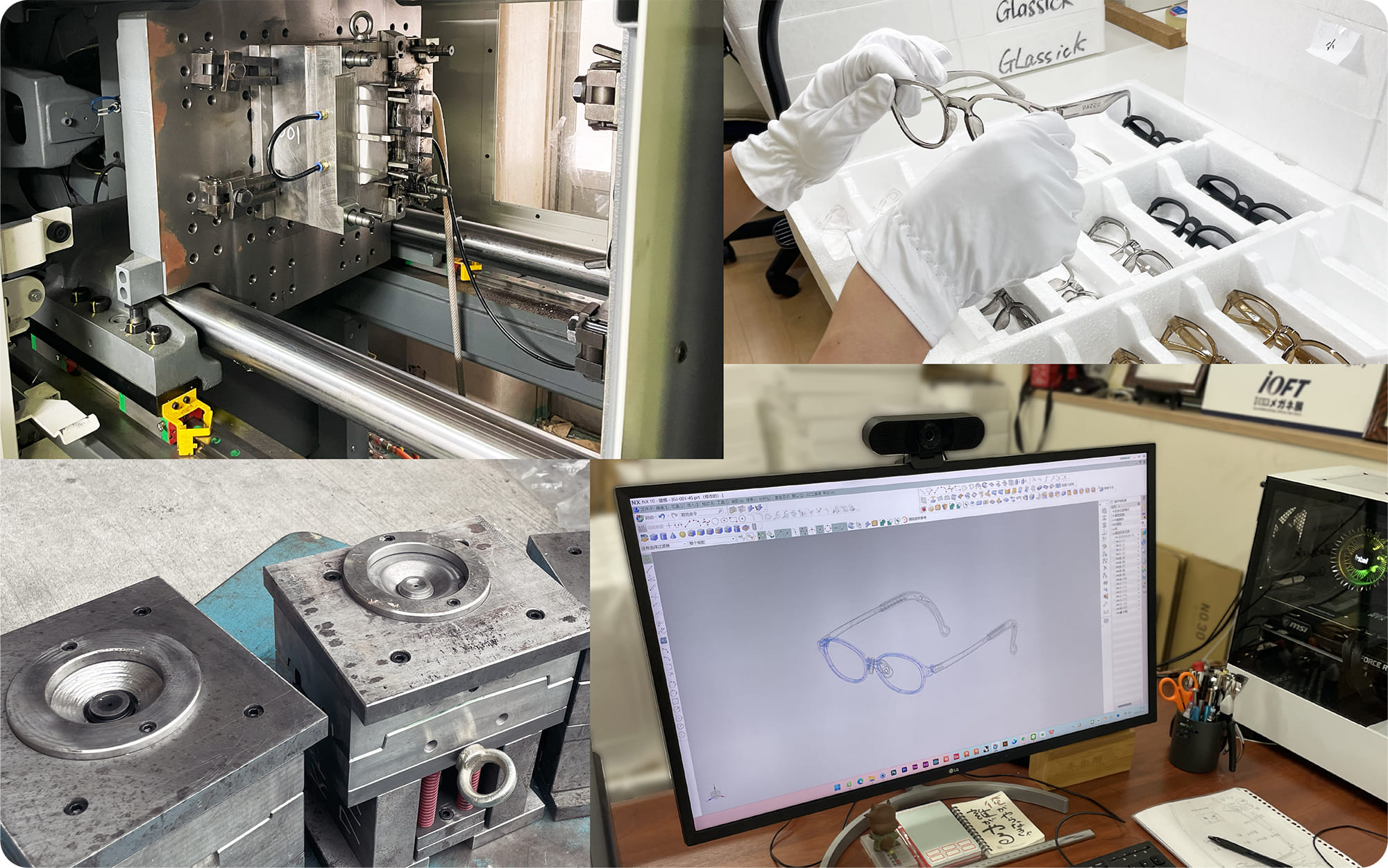

We do in-house production from design to completed product.

This is achievable due to our impressive technical expertise and experience.

Product planning

Planning and development

We can appropriately develop products based on your requirements and quality standards.

We consider not only design and pricing but also requirements such as materials and structure in our product planning. Also,we develop products based on international standards such as FDA certification and CE declaration.

Design

Both 2D and 3D designs make it easier to imagine the shape of the product.

We make 3D drawings, which makes it easier to envision the final product.This allow us to vertify the shape and structure, enabling djustments and modifications at the drawing stage.

Design examination

We can examine and make adjusments for strength and manufacturing issues based on 3D CAD data.

Strength and manufacturable size are different depending on the materials used. Considering this,we examine the structure and manufacturing issues in the 3D CAD data. If necessary,we redesign it to ensure the perfect product.

Sample examination

We examine the design and structure using a mockup made with a 3D printer for final evaluation.

A mockup made with a 3D printer makes it easy for us to envision the product.This allows us to physically confirm aspects like fitting and size when worn. At this stage, we can make fine adjustments to achieve a more perfect product .

Mass production

Molding process

We do injection molding on an automated manufacturing line 24/7.

We use environmentally friendly materials such as plant-based resins and recycled plastics,as well as durable engineering plastics, to achive high-performance, high-quality molding.To keep costs low, we maintain 24/7 operations with automated manufacturing lines.

Quality inspection

We inspect the molded parts to ensure there are no defects or problems.

In addition to simple defects such as foreign particles and deformities, our inspectors carefully examine factors like surface smoothness and strength one by one.

Surface finishing

We apply printing to the product’s surface using our original skill.

Printing on three-dimensional objects or curved surfaces is not achievable with standard techniques. We have the skill to to do so. We offer full-color printing with various colors and textures, as well as non-peeling, impreqnation printing.

Assembling and adjustment

The components are assembled, and final adjustments are made for shipping.

After surface treatment, we assemble componets, put lenses, adjust alignment and clean them. We prepare them for shipment at any time.

Shipping

The finished products are placed into bags,packed, and shipped.